| No | Project name | Construction scale | Main process | Operation time |

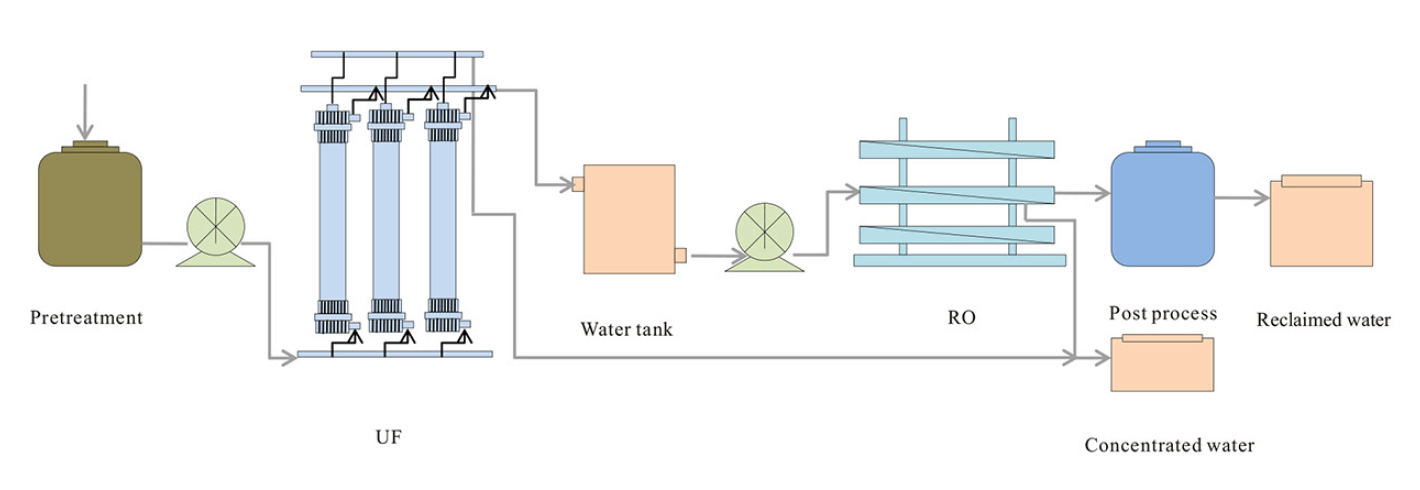

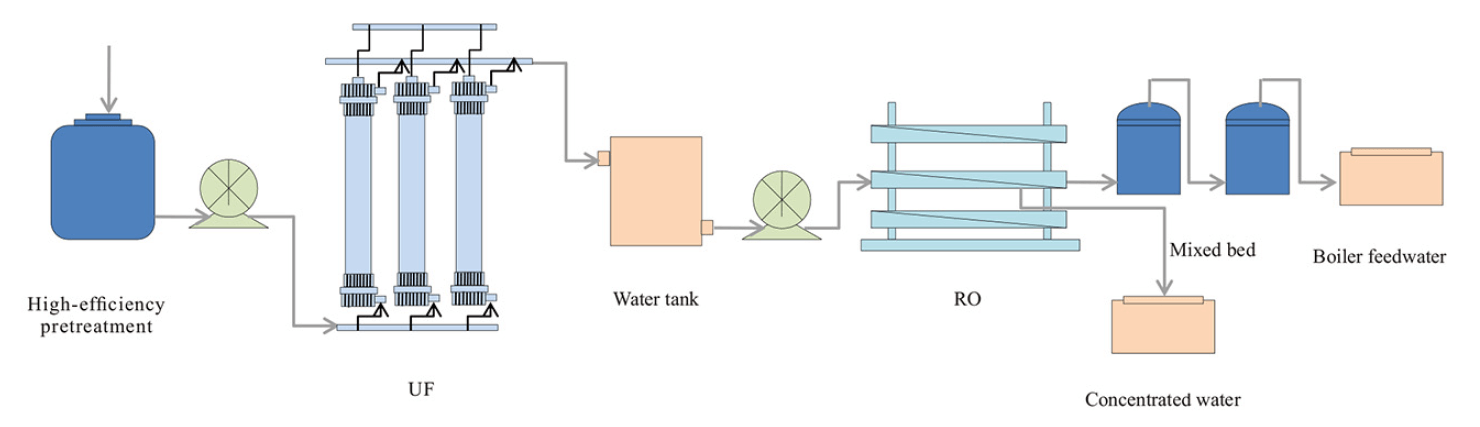

| 1 | Municipal Wastewater Recycling | 50000 t/d | Pretreatment + UF + RO | 2019 |

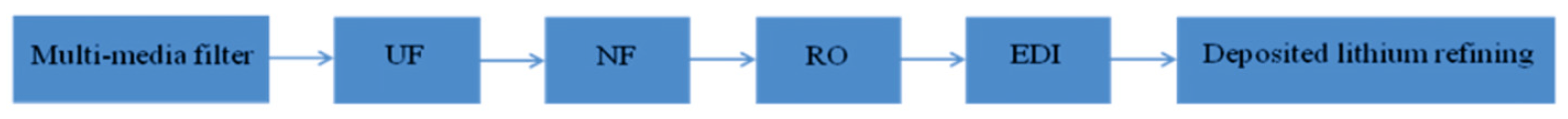

| 2 | Steel Wastewater Reuse | 50000 t/d | Pretreatment + UF + RO + EDI | 2018 |

| 3 | Metallurgical Wastewater Reuse | 3500 m3/d | Pretreatment + UF + RO + ED + MVR | 2017 |

| 4 | Papermaking Wastewater Treatment | 25000 m3/d | Pretreatment + UF+ RO | 2016 |

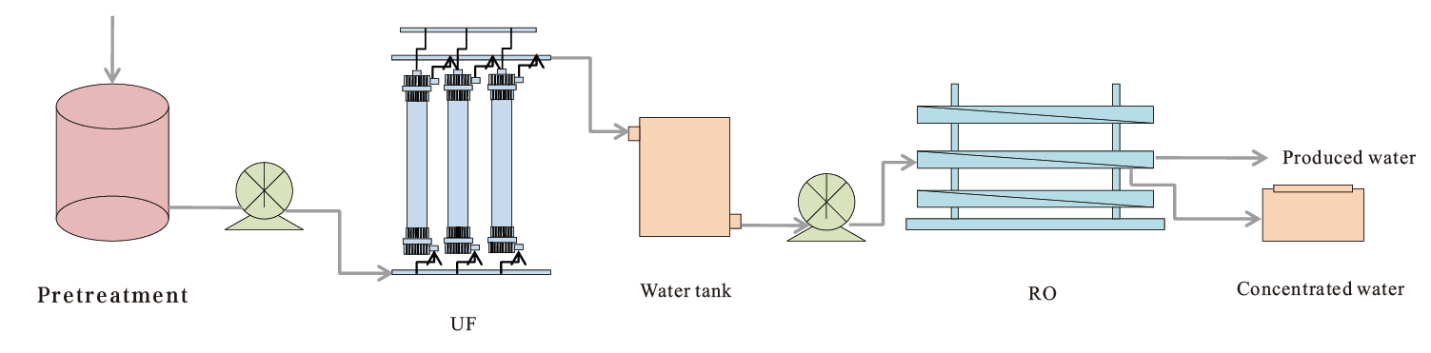

| 5 | Desalination Water Treatment | 8000 m3/d | Pretreatment + UF + RO | 2016 |

| 6 | Chemical Wastewater Reuse | 4500 m3/d | O₃ + UF + RO | 2016 |

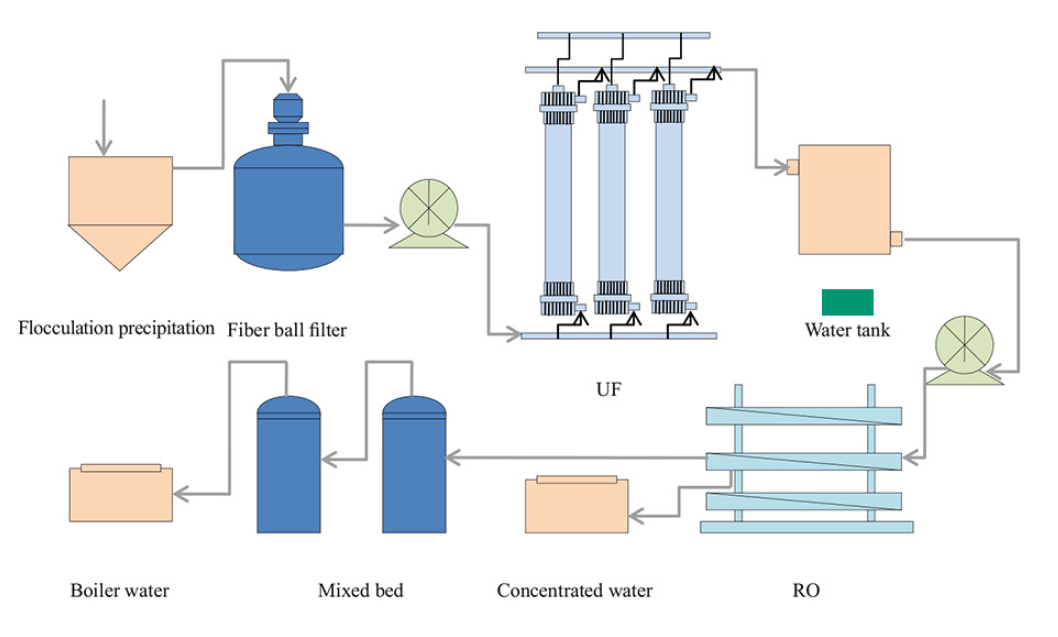

| 7 | Power Plant Wastewater Reuse | 14400 m3/d | Pretreatment + UF + RO + Mixed bed | 2016 |

| 8 | Papermaking Wastewater Reuse | 22800 m3/d | O₃ + UF + RO | 2016 |

| 9 | Pharmaceutical Wastewater Reuse | 20000 m3/d | O₃ + UF + RO | 2015 |

| 10 | Wastewater Reuse | 4400 m3/d | Pretreatment + UF + RO | 2014 |

| 11 | High-Concentrated Chemical Wastewater Reuse | 500 m3/d | Pretreatment + UF + RO | 2014 |

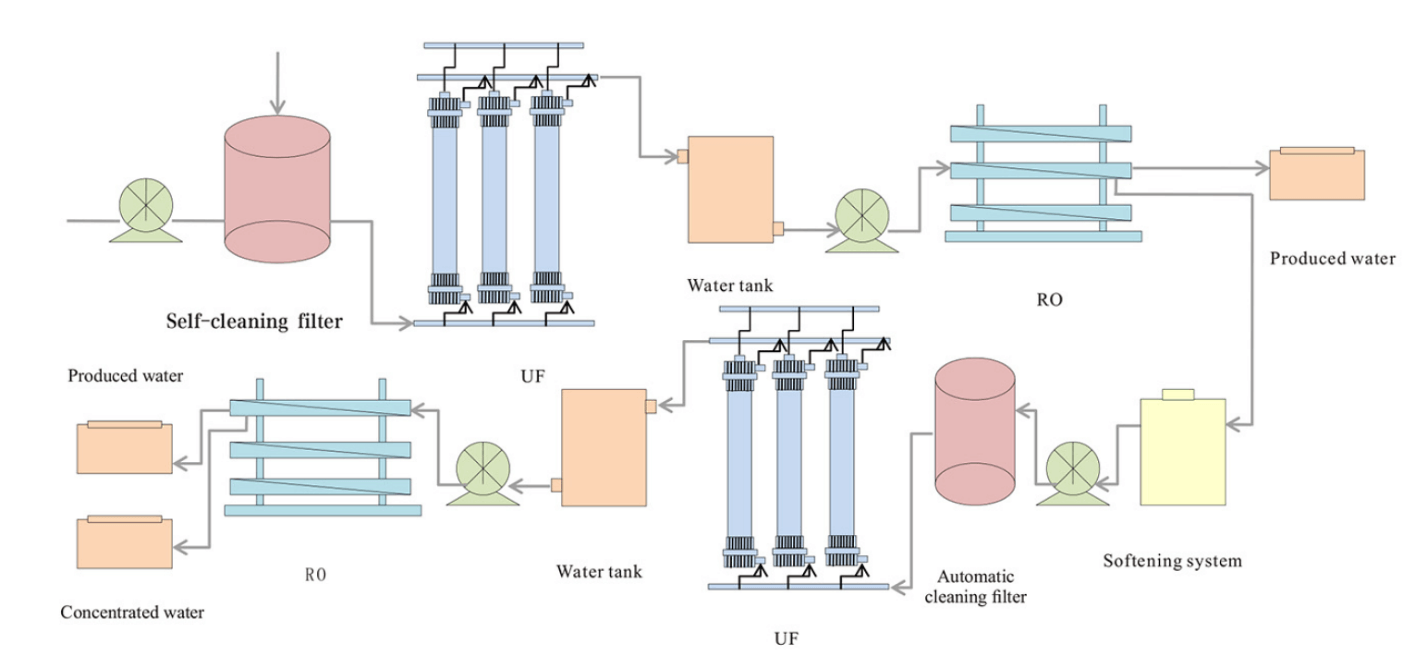

| 12 | Demonstration Project of Wastewater Reuse | 40000 m3/d | Membranes Integrated Systems | 2013 |

| 13 | Power Plant Wastewater Reuse | 12000 m3/d | Pretreatment + UF + RO + Mixed bed | 2013 |

| 14 | Highly Polluted Surface Water Purification | 12000 m3/d | Pretreatment + UF | 2013 |

| 15 | Pharmaceutical Wastewater Reuse | 18000 m3/d | Pretreatment + UF + RO + Mixed bed | 2012 |